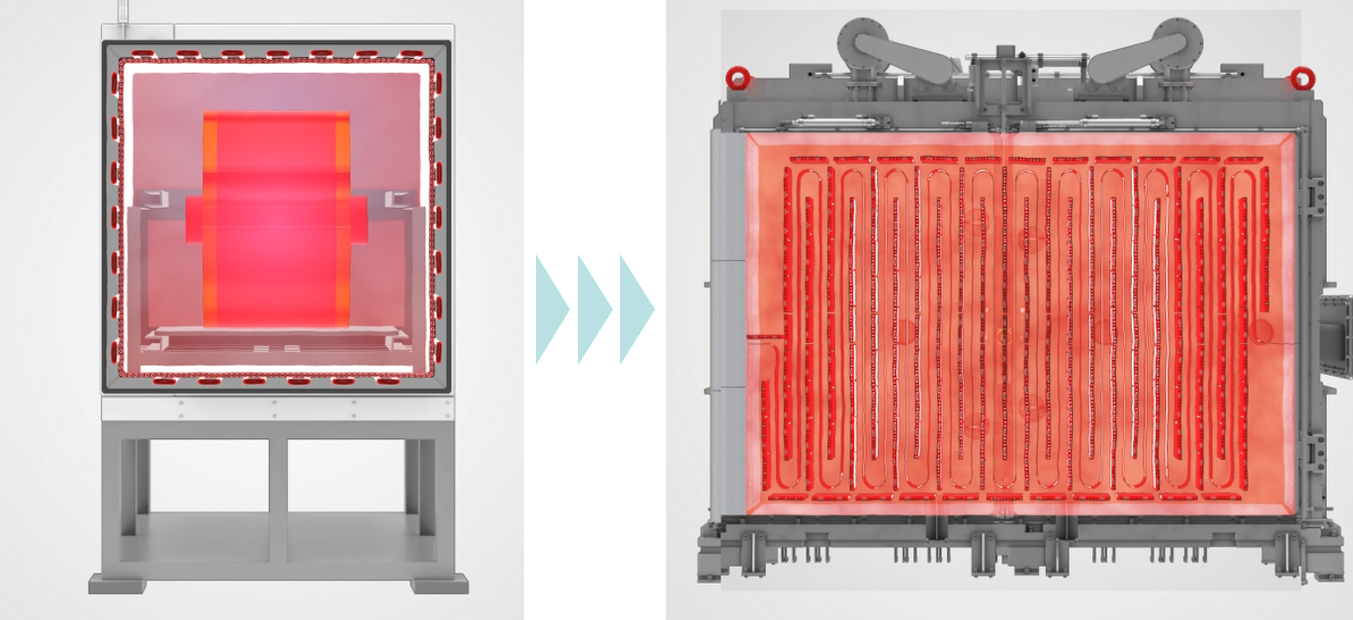

- Uniform Heating

RtoR drying is a continuous process where the electrode material is coated onto a flexible substrate in a continuous web format. Compared to conventional roll drying, RtoR processing provides uniform product quality.

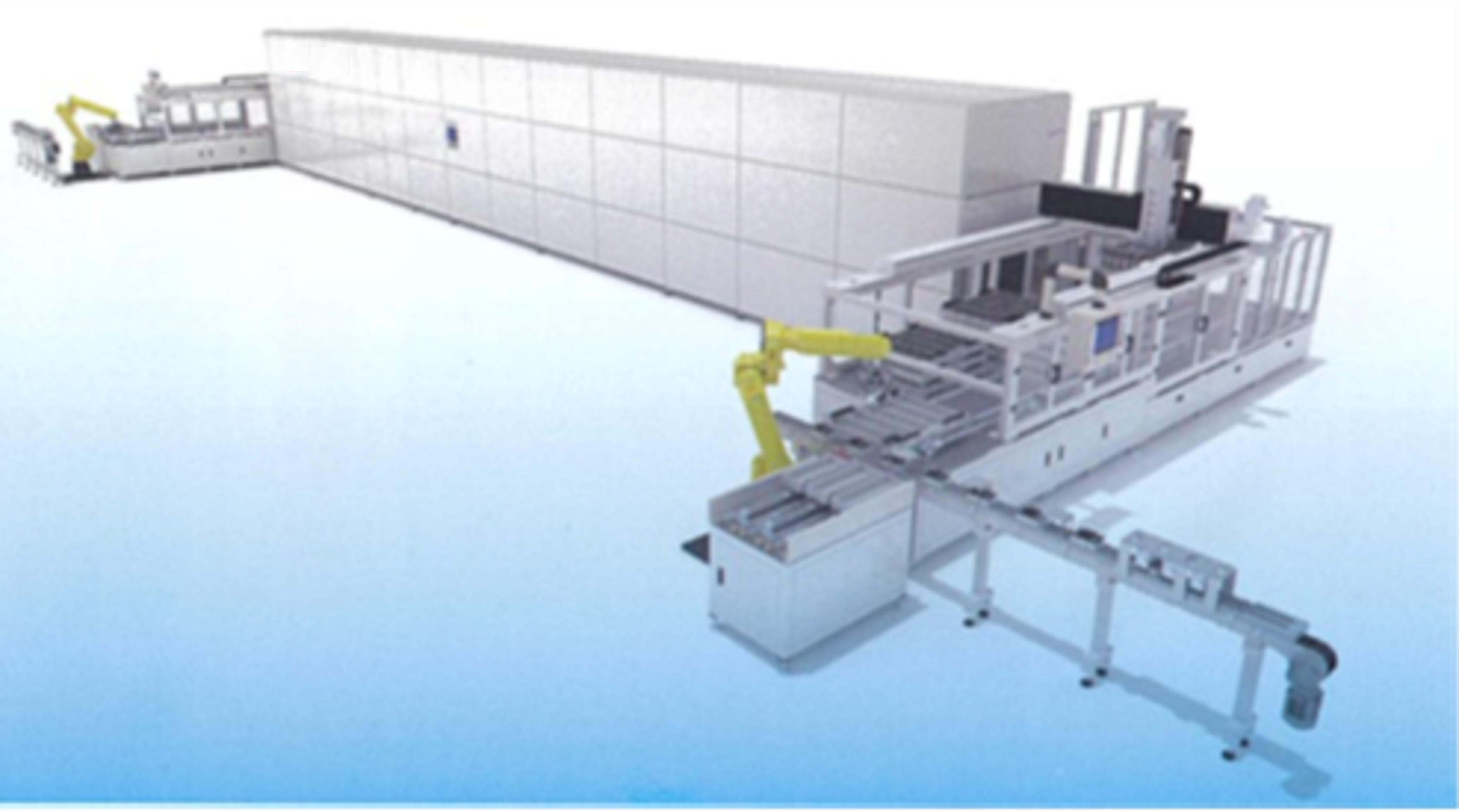

- Reduced Drying Time

RtoR drying is designed for high-throughput production, making it suitable for large-scale manufacturing. It allows for the efficient processing of electrode materials in large volumes. Compared to conventional roll drying, RtoR processing significantly reduces processing time. (12hr→0.6hr)

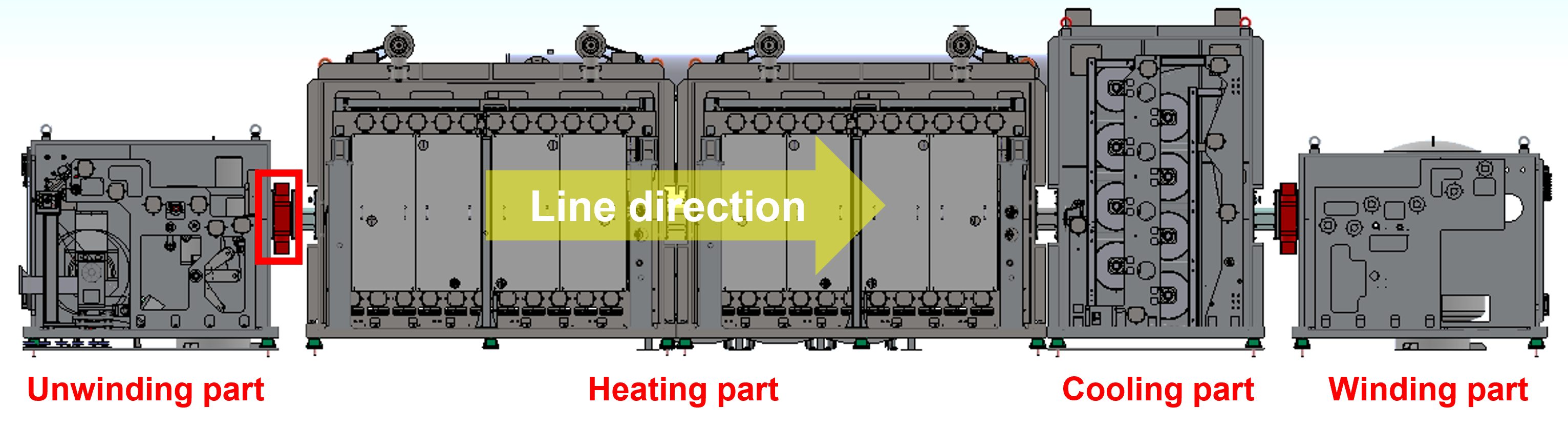

- Space Saving

The vertical arrangement of the heaters reduce the installation space to 1/10 compared to the horizontal arrangement.

- Lead time reduction

By adopting a gate valve mechanism, the lead time for product replacement is greatly reduced.

- Energy Saving

Since the conventional vacuum heating systems uses nitrogen (N2) to make a "vacuum" atmosphere, the operational cost is significantly high. Also, the structure of the RtoR drying system has a significantly smaller chamber than the conventional systems, power consumption is also dramatically lower.

It is estimated have approx. 50% lower power consumption and 100% less nitrogen (not necessary) compared to convetional systems which also has a large impact to CO2 emission!

If you have any questions or need more information, please contact us through the inquiry form.

Contact Here