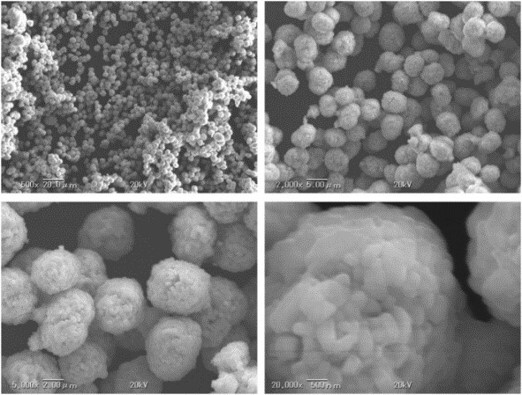

In our extensive experience, we have successfully handled a diverse range of battery materials, including cathode active materials like NCM and LFP, anode materials such as silicon anode. This breadth of expertise empowers us to deliver tailored solutions that meet the intricate demands of battery material production.

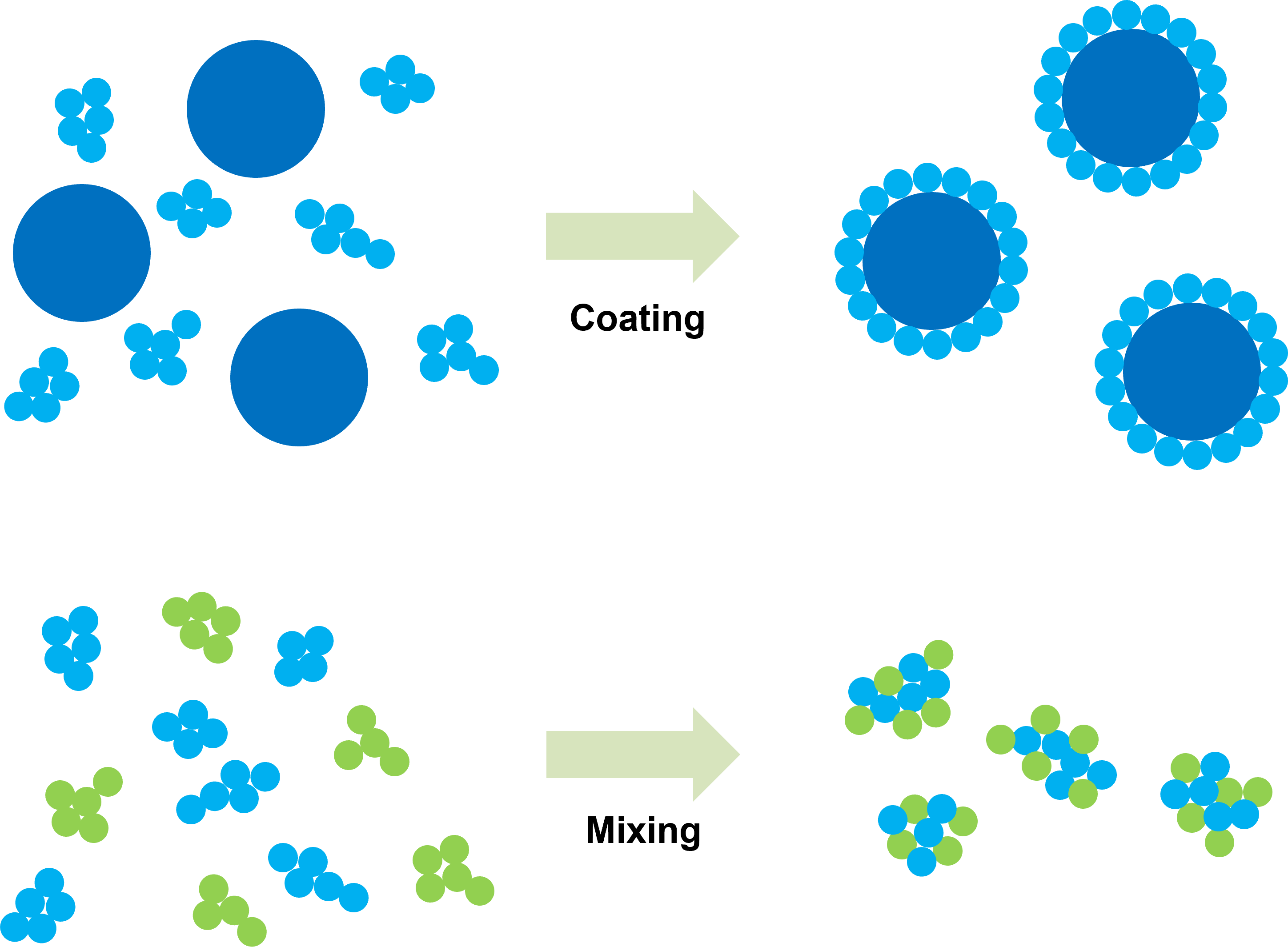

Solid-state batteries rely on the interface between the cathode active material and the solid electrolyte for ion conduction. Coating the cathode active material with a thin, protective layer stabilizes this interface, preventing undesirable reactions and improving overall battery performance.

In the realm of solid-state battery technology, electrode coatings for cathode active materials play a pivotal role. By stabilizing interfaces, reducing resistance, enhancing cyclability, minimizing side reactions, and boosting safety, these coatings are integral to achieving high-performance solid-state batteries that are not only efficient but also reliable and safe.

If you have any questions or need more information, please contact us through the inquiry form.

Contact Here