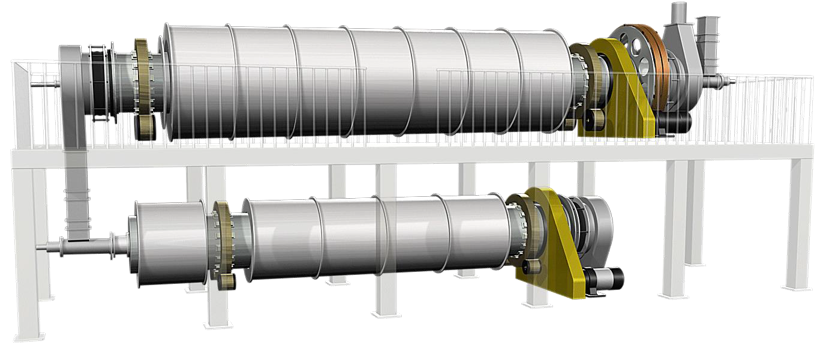

A rotary kiln is a cylindrical, inclined, and rotating device used for a variety of processes, including heating, calcination, drying, and more. It's essentially a large, industrial-scale furnace with a rotating drum. The rotation is usually slow and continuous, allowing materials to be processed evenly as they move through the kiln. In battery material production, a rotary kiln is often utilized for the drying lithium hydroxide and coating for cathode active mateials.

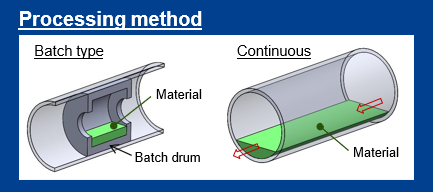

Rotary kilns can essentially be designed in two different types: a batch type and a continuous type. In our experience, the majority of customers producing battery materials prefer the continuous type to take advantage of the throughput (kg/h) for mass production.

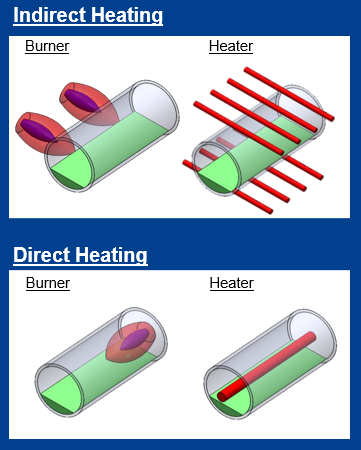

Various heating methods exist, but due to the recent trends in ESG, most customers opt for heaters powered by electrical resistance. We recommend utilizing electrical heaters powered by renewable energy for global sustainability.

Considering the recent production process for any precursors or most cathode active materials, the drying process is one of the most crucial steps in the entire production line.

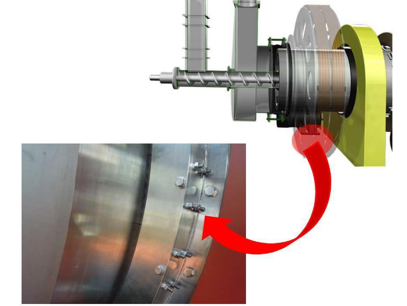

One of the critical aspects of rotary kilns for battery materials applications is gas tightness and tube material.

Gas tightness is crucial because, in some cases, rotary kilns are utilized for coating cathode active materials using a special gas atmosphere. In such instances, gas leakages and oxygen concentration must be minimized. Our rotary kiln features a special seal structure designed to secure the gas atmosphere and minimize gas leakage, achieved by using a special carbon material for the seals.

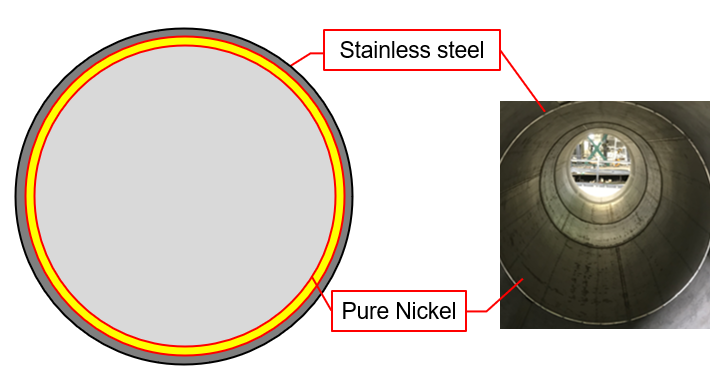

Regarding the tube material, we offer several options based on the customer's request. One major concern we address is lithium corrosion, which typically results from a chemical reaction between chromium in the tube material and lithium in the battery material. We mitigate this issue by employing a special pure nickel tube that has undergone rigorous testing by major global players in the battery materials industry.

If you have any questions or need more information, please contact us through the inquiry form.

Contact Here