Mixing process is to make slurry by active material, conductive material, binder and solvent, and ensure uniform distribution by accuarately inputting through metering, mixing and stiming by powder supply device.

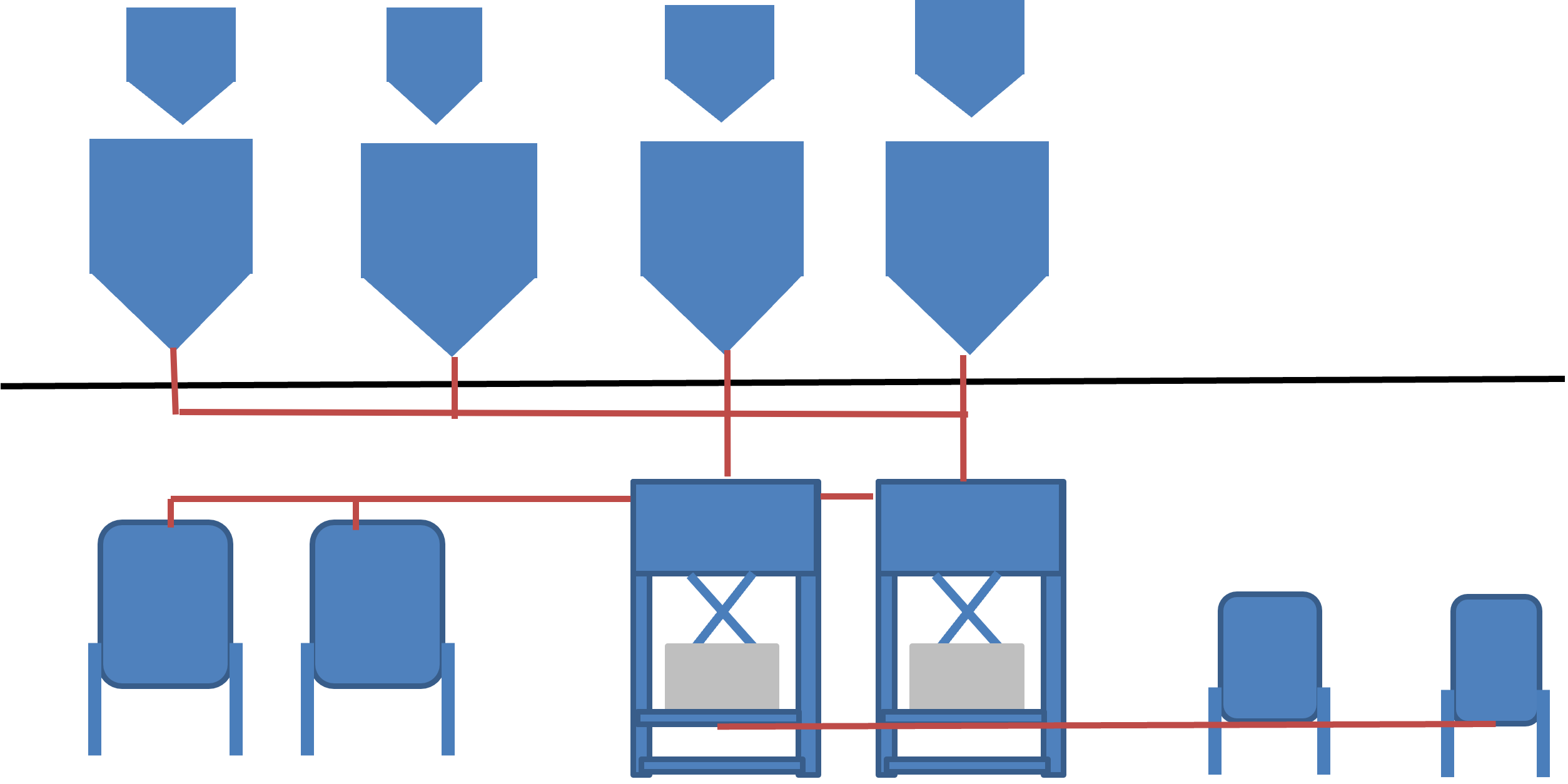

The mixing process usually consists of the following process .

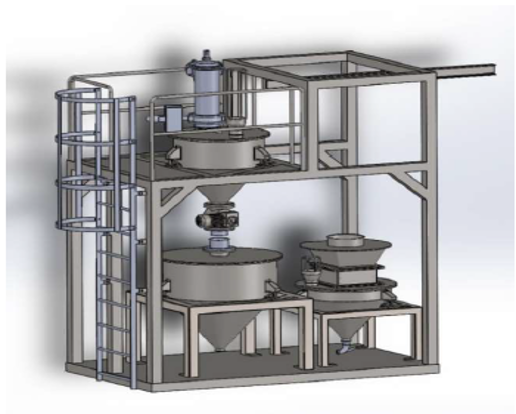

PTS(Powder Transfer System) is to transfer powder quntitively and smoothly by using air or vacuum.

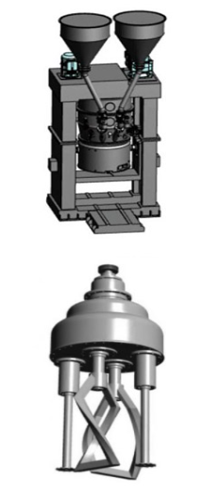

PD mxier has twist blades to generate big power for Kneading and stirring, and have despa for high spped disperion at the same time.

Because of efficient mixing and high volumn, PD mixer is the most common mixer used in manufacturing secondary battery slurry equiment.

If you have any questions or need more information, please contact us through the inquiry form.

Contact Here