Have you ever considered acquiring a batch kiln or oven for your laboratory? If you are an R&D specialist or a researcher focused on battery materials, we are confident that this idea has crossed your mind.

Typically, the available ovens are designed for heating very small quantities of materials, and options for heating with an inert gas or oxygen atmosphere are limited.

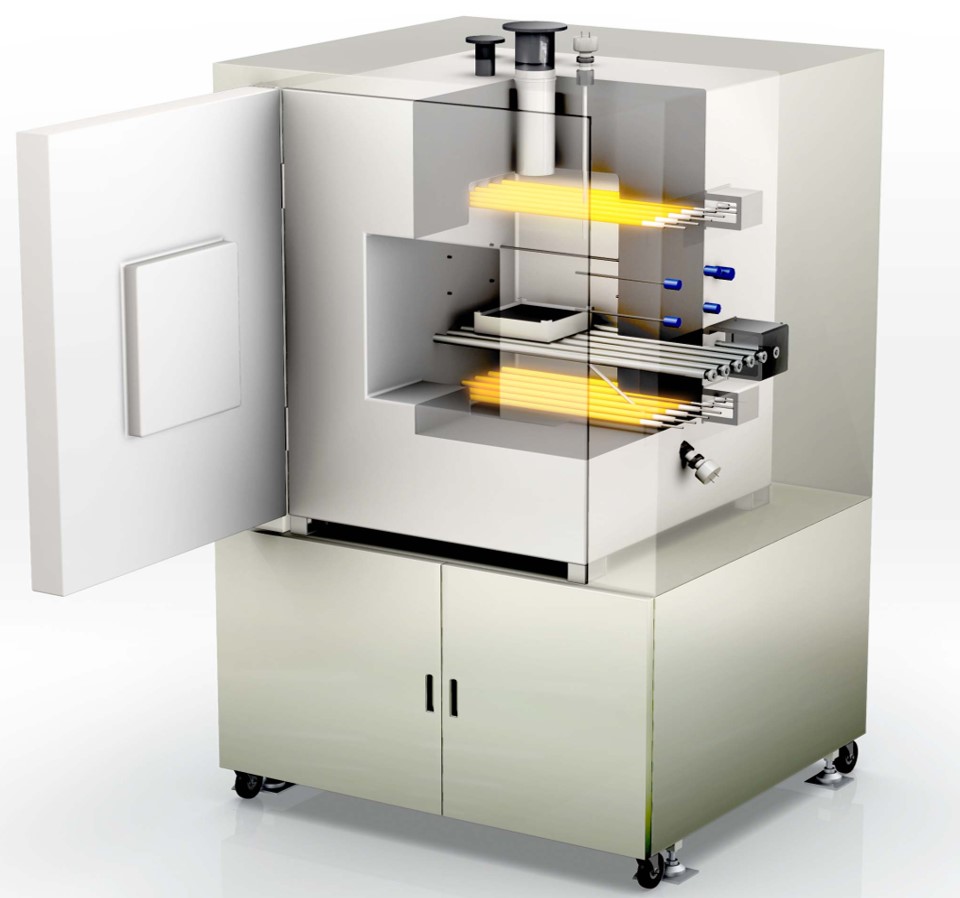

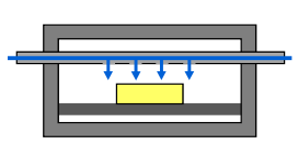

Introducing our RHK-Simulator (RHK-S), a batch kiln meticulously designed based on a mass-production RHK (roller hearth kiln), faithfully replicating its exact structure. The key distinction between standard small ovens and the RHK-S lies in the ability to evaluate your battery materials with the same precision as a mass-production RHK.

It is capable of using same size saggars and cruciables as the mass-production RHK, which would roughly be around 330 x 330 x 80~120mmH.

We have developed a standardized model for the RHK-S, eliminating the need for an expensive design fee. This model is tailored specifically for heating battery raw materials, and we offer several options for a more efficient and user-friendly control system for the RHK-S.

Being a certified global distributor of Noritake Co., Ltd., we have delivered many of RHK-S to worldwide battery materials market leaders for their lab and pilot plants.

- Several sizes available: 1 sagger, 2 saggers, 4 saggers, 8 saggers

- Footprint:

- 1830mmW×1400mmD (1 & 2 saggar type)

- 2160mmW×1550mmD (4 & 8 saggar type)

- Designed for any type of cathode active materials, LCO, NCM, NCA, LFP and anode materials etc.

- Gas tight design for firing in gas atmospheres

- Sagger size: Up to 330 x 330 x 130mmH

- Temperature ramp up: 300℃/h

- Maximum temperature: 1050℃

- Atmosphere: N2, O2

- Utility: 3phase 400V, SCR: 25kA

- Integrated control panel (below the chamber)

- Additional gas purge (from the side, top)

- Touch panels for easier temperature control

- Mass flow meter for easier gas control

If you have any questions or need more information, please contact us through the inquiry form.

Contact Here