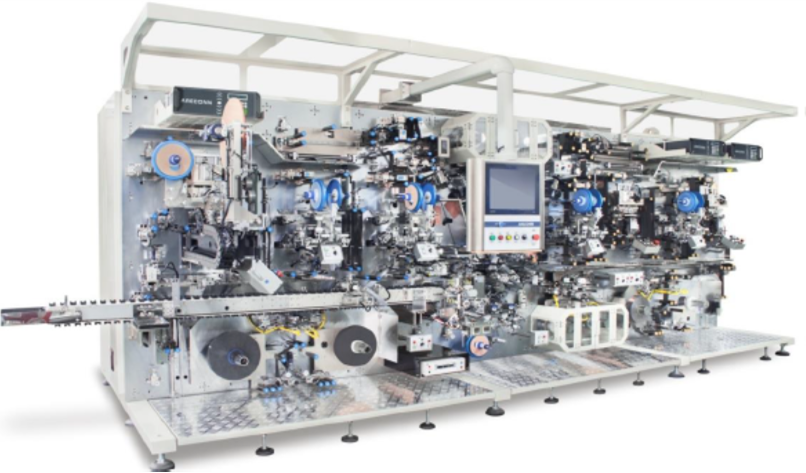

This machine is for the cylindrical battery manufacturing equipment. After the equipment is used for positive and negative film unwinding and rectification, the positive/negative tab is ultrasonically welded and glued. After the electrode is inserted into the film, it is wound into a cylindrical battery cell together with the separator. After cutting/ attaching protective tape/ hot hole and measuring/ the short circuit checked, it is finally sent out by the conveyor belt.

・Electrode automatic roll change

・Separator automatic roll change

・Segmented tension automatic Control

・Ultrasonic welding system

・Dust removal system

・Hi-pot testing function

・Three-axis automatic winding

・Positive and negative electrode tape device

・Double station cutting, high speed stability

・Edge positioning correction control

・Cell hot hole

The equipment is mainly used for the winding of the prismatic battery cell, the coil material is supplied to the electrode and the separator, and the positive and negative electrode sheets and the diaphragm are wound to complete the cell bare core. Three-station operation: one station into the film winding, two stations for finishing glue, three stations for unloading. Automatic test for short circuit, weighing, and defective product rejection.

・Dust removal system

・Segmented tension

・automatic control

・PC control

・Positive electrode cutting and taping device

・CCD overhang detection

・Battery shape detection

・Hi-pot test function

・Electrode automatic roll change

・Separator automatic roll change

・3 axles automatic roll change

If you have any questions or need more information, please contact us through the inquiry form.

Contact Here